How to Get Kids Started with 3D Printing

A parent's guide to starting your child on a creative 3D printing adventure, without breaking the budget.

Table of Contents

A parent's guide to starting your child on a 3D printing adventure, without destroying the budget.

Benefits of 3D Printing for STEM Education

3D printing provides K-12 students with the opportunity to get hands-on experience with cutting-edge technology.

By learning how to design and print their own creations, students can develop valuable problem-solving and critical thinking skills while also fostering their creativity and imagination.

This type of hands-on learning can be more engaging and memorable than traditional school assignments, helping cultivate a sense of joy and excitement in learning.

Getting Started with 3D Printing

3D printers can be incredibly useful for addressing practical household issues, such as fixing broken items or customizing decor. 3D printers provide endless opportunities for entertainment, such as creating miniatures for tabletop gaming or toys.

The 3D Printing Process:

- Get a digital 3D model, by downloading open-source designs or creating your own with computer-aided design (CAD) software.

- Slice the 3D model, which translates the design into instructions for the printer.

- Print your design (expect to adjust/fine-tune along the way)

- Post-process (remove support material, painting, sanding)

3D Printers by Budget

For up-to-date purchase advice, checkout Reddit's /r/3Dprinting Purchase Advice Megathead (pinned).

Under $200

The printers in this category require hands-on assembly and calibration (bed leveling). This category is best-suited for beginners up for a challenge, who don't mind repetitive fiddling/tuning in order to achieve great results.

If you find yourself easily frustrated by fiddling/tuning tasks, you might prefer a more expensive model with automated bed leveling.

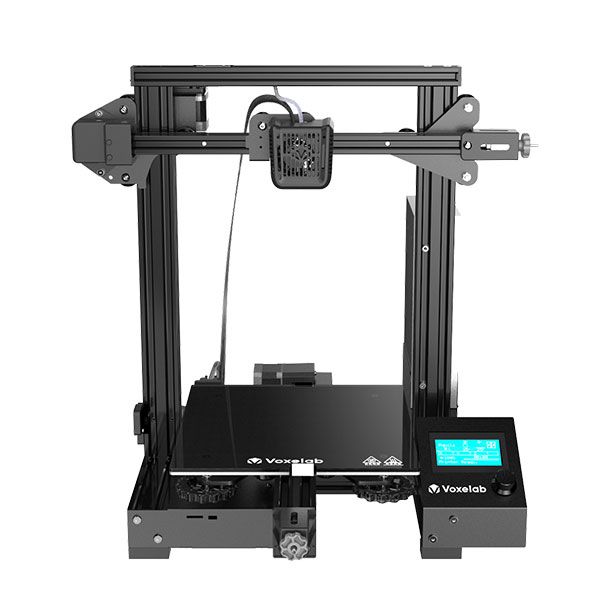

Voxelab Aquila C2

The Voxelab Aquila was selected by all3dp.com as the best 3D printer under $200 in 2021. The design is similar to the Creality Ender 3, with a slightly lower price point.

- Product page: Voxelab Acquila C2

- Price range: $165 - $180

- Build volume: 220 x 220 x 250 mm

- Ideal user: Beginner/hobbyist

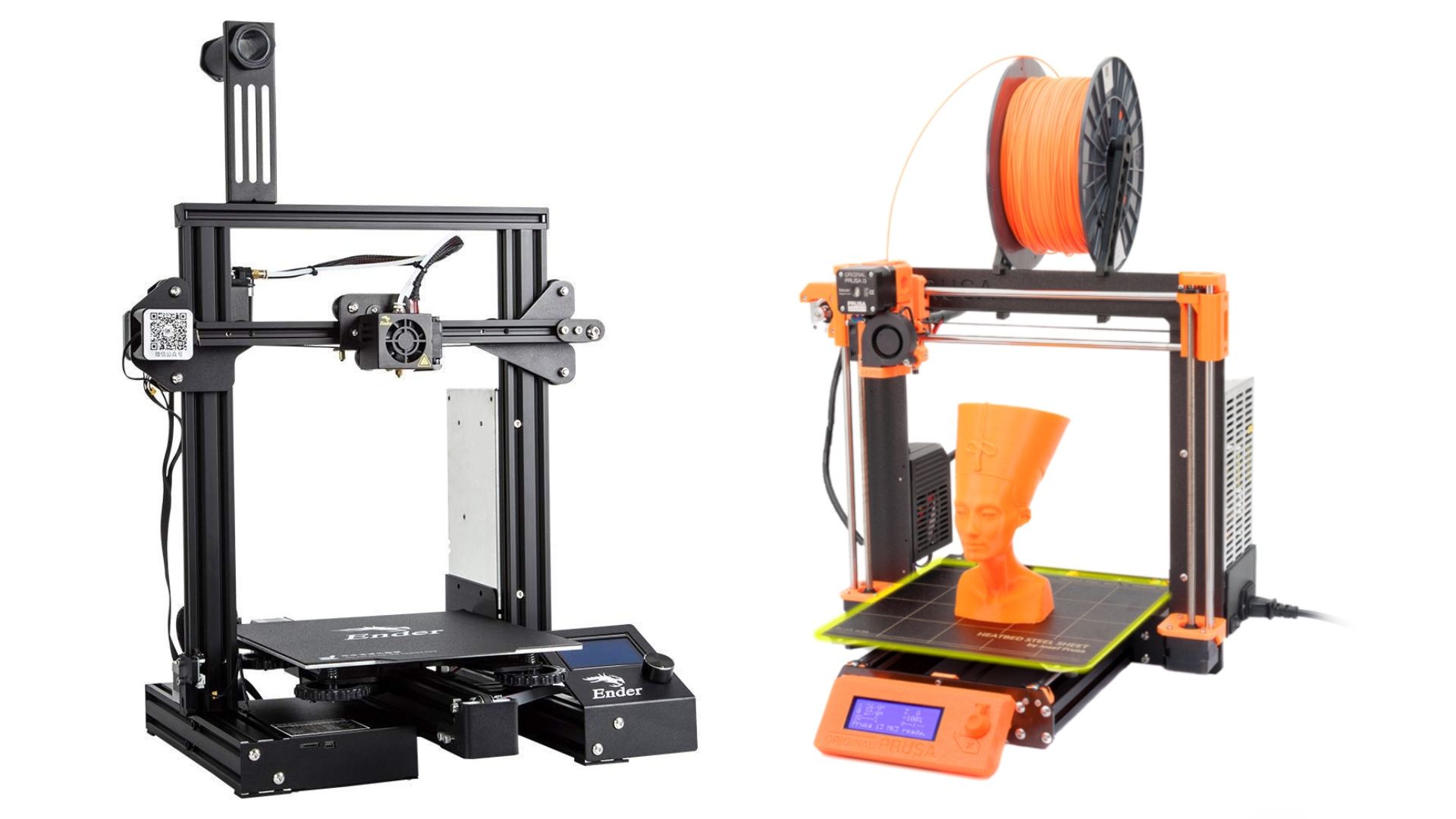

Creality Ender 3

The Creality Ender 3 is designed to be easy to assemble, with most users being able to complete the process in less than an hour.

The Ender 3 is an affordable 3D printer, making it a popular choice among beginners, hobbyists, and educators on a tight budget.

- Product page: Creality Ender 3

- Price range: $179 - $199

- Build volume: 220 x 220 x 250 mm

- Ideal user: Beginner/hobbyist

$200 - $500

3D Printers in this category come with extra features and quality-of-life improvements, like auto-bed leveling and a sensor that detects when filament runs out.

Artillery Genius Pro

Overall, the Artillery Genius Pro is a versatile and capable 3D printer that offers advanced features like auto-bed leveling and an extruder capable of handling high-temperature materials.

- Product page: Artillery Genius Pro

- Price range: $320 - 350

- Build volume: 220 x 220 x 250 mm

- Ideal user: Beginner/hobbyist, design professionals

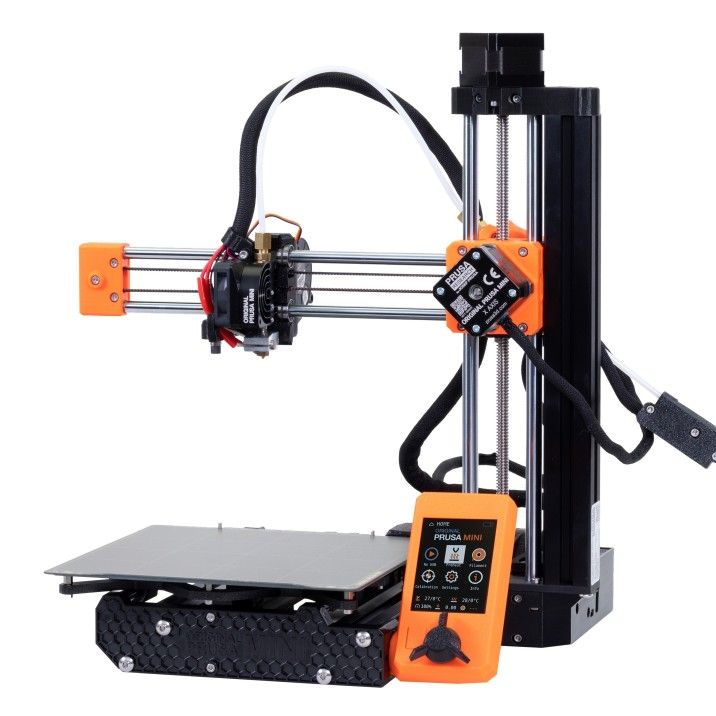

Prusa MINI+

The Prusa MINI is a compact 3D printer, with a 180 x 180 x 180 mm build volume. Prusa has a positive reputation for their open-source contributions to the 3D printing ecosystem.

The MINI is available as a fully self-assembled kit, or partially-assembled.

- Product page: Original Prusa MINI+

- Price range: $429 - $459

- Build volume: 180 x 180 x 180 mm

- Ideal user: Beginner/hobbyist, design professionals

Different Kinds of Additive Processes

The 3D printers above use a process known as Fused Filament Fabrication (FFF). FFF is one of many kinds of 3D printing processes, known collectively as additive manufacturing processes.

Other processes are more suitable for industrial design, so we recommend sticking to FFF for kids projects. We've included a brief description of each process to help navigate the alphabet soup of 3D printing technology.

Fused Filament Fabrication (FFF)

FFF 3D printers use a heated nozzle to melt a plastic filament and deposit it layer by layer to build a 3D object. The melted filament is extruded from the nozzle, building up the object layer by layer until it is complete.

FFF 3D printers are relatively low cost and widely available, making them a popular choice for hobbyists, educators, and small businesses.

Stereolithography (SLA)

SLA 3D printers use a laser to cure a liquid resin layer by layer into a solid object. The laser traces the cross-section of each layer on the surface of the resin, causing it to solidify.

SLA 3D printers are capable of producing high-resolution parts with fine details, making them well-suited for applications that require high accuracy and surface finish.

However, SLA 3D printing is also one of the more expensive 3D printing technologies and is typically used in applications that require high-quality prototypes or low-volume production of small parts.

SLA printing requires handling hazardous and toxic materials.

Selective Laser Sintering (SLS)

SLS 3D printers use a laser to fuse together small particles of material, such as nylon, to build a 3D object. The laser selectively fuses the particles where they are needed, creating a solid object.

SLS 3D printers are more expensive than FFF 3D printers, but they offer several advantages, including higher resolution, greater strength, and the ability to print objects with complex geometries. SLS 3D printing is often used in industries such as aerospace, automotive, and healthcare, where high-quality, durable parts are needed.

Project Inspiration

PrintNanny Newsletter

Subscribe to receive cool project inspiration.

Pick a Unique Constraint for Projects

- Sound: design a 3D printed object that makes an interesting sound, like a velociraptor call.

- Tiny Treasures: print an object no larger than 1 inch in any dimension

- One-Hour Wonders: all prints must take less than 60 minutes to finish.

- Miniature Marvels: print a scale model of a real-world object.

- Print-in-Place: print an object that can be assembled without the need for any additional tools or components.

- Sustainably Sourced: print an object that is made from recycled or biodegradable materials,

Where to find 3D Model Designs

The sites below host a mix of open-source (free) models and paid professional designs.

- https://cults3d.com/

- https://www.printables.com/

- https://www.thingiverse.com/

- https://thangs.com/

- https://www.myminifactory.com/

- https://www.yeggi.com/

- https://grabcad.com/

- https://www.youmagine.com/

Resources

Reddit /r/3DPrinting Wiki

The /r/3DPrinting Wiki is a wealth of information about 3D printing, with information laid out in a friendly way for beginners and hobbyists.

- Troubleshooting & Calibration

- Printer & Movement Styles

- Hardware & Upgrades

- Slicers

- Materials

- Print, Design and Model-Host Services

- Making Models

- Firmware & Gcode

- Post Processing

- Resin Printing

- Special Techniques & Goals

- Buying a Printer

- Replacing Pressed Gears

Local Library Branch

Many libraries now have dedicated 3D printing labs, where users can bring in their designs and print them on the library's 3D printers. This can be a valuable resource for anyone looking to try 3D printing for the first time, or for more experienced users who are looking for a convenient and affordable printing option.

In addition to providing access to 3D printers, many libraries offer workshops and classes on 3D printing, providing patrons with the opportunity to learn about the technology and its applications. These workshops can cover a variety of topics, including how to use 3D printing software, how to create and prepare designs for printing, and how to troubleshoot common printing problems.

Comment below to us about it!

PrintNanny.ai Newsletter

Join the newsletter to receive the latest updates in your inbox.